Low Volume Production

(Section 1) Low-volume production is often overlooked by high-volume projects. Low-volume is rarely catered to or even acknowledged by suppliers or customers. In this three part series, I would like to discuss today’s methods of manufacturing for low-volume production plastic parts. Times are changing and engineers and buyers are slow to make the adjustment.

Part One will talk about and identify today’s methods of low-volume production. We will discuss new technologies and show how old technologies are being used in a new way. We will define low-volume production in the plastics world along with explaining why it needs to be dealt with differently than high-volume production. Part two of this series will discuss what you should look for when choosing your low-volume production application. We will break down components that will assist you in your decision making from complexity of the part to functional material options. Myths of Rapid Tooling will be dispelled along with showing real examples of successes. The third and final part of the series will show pricing comparisons between Direct Digital Manufacturing (DDM) and Rapid Tooling. We will show where the breakeven points are in quantity vs. cost and complexity. Real life projects will be shared with my closing thoughts on the future of low-volume production.

PART 1:

Before we look at today’s manufacturing trends, we must first take a step back and identify today’s product trends. The product trend*s from companies are to have more products and have them released faster than ever before. These products are more customized and are filling more niche markets. The products are quickly updated for the next iterations to keep “new” products in front of consumers. This new trend for products has made them lower in volume, but higher in margin.

Now let’s look at the trends of prototyping these products. This is the first time in my 12 year experience in this industry that speed has not been the number one demand. There is a need for speed, but not a greed for speed. Function, function and function is where it is at. Engineers need their prototypes to work across the board. These parts need to fulfill the needs for engineering, packaging, focus groups and field tests. It does not matter how fast the prototypes are completed if they do not work for all purposes. These prototypes need to be made from a spec material for real testing and hold production like tolerances.

TRADITIONAL MANUFACTURING FOR LOW-VOLUME PRODUCTION PLASTIC PARTS

Notice there have been three rings with very little overlap from one to another. Specific technology was used only for a specific ring of manufacturing. Technologies did not cross

from rapid prototyping to production. With the advancement in technology and thought process, the rings have been redefined into Today’s Manufacturing. Techniques, methods and technologies in Rapid Prototyping have crossed over into production. Many methods in Bridge Tooling or Rapid Tooling are successful in low-volume production. Along with the advancements comes a new terminology call Direct Digital Manufacturing (DDM).

What is DDM?

DDM is defined as a direct production of finished goods from additive manufacturing technologies. Or, DDM is the process of going directly from an electronic digital representation of a part to the final product via additive manufacturing. DDM has joined the likes of Bridge Tooling and Pre-Production (Rapid Tooling) as a legitimate method of low-volume production. The most common technologies that are used in DDM are FDM (Fused Deposition Modeling) from Stratasys and SLS (Selective Laser Sintering) from 3D Systems and EOS. These parts are built using an additive process then are used as an end product in low-volume production. The materials have become rigid enough for true function. The FDM process is building plastic parts from materials such as ABS, Polycarbonate (PC) and Polyphenylsulfonen (PPSF).

Low Volume Production (Section 2)

In part one of this three-part series, we discussed today’s methods for managing “low-volume production.” Defining what volumes should be called low-volume, and explaining why low-volume production needs to be dealt with differently than high-volume production. Comparing traditional manufacturing techniques with today’s by highlighting two technologies for low-volume production, Direct Digital Manufacturing (DDM) and High Speed Milling for Rapid Tooling (RT).

This article is designed to help you decide which method of low-volume production you should choose. We will also dispel some myths of Rapid Tooling and show real life examples of low-volume production successes.

CHOOSING RT OR DDM

When should you choose one over the other? Let’s start by defining DDM as the direct production of a finished good from an electronic (digital) representation of a part, using a software program to place material in a three-dimensional space (a three-dimensional printer). We have identified seven attributes of the finished part for you to consider when choosing between DDM and RT.

Part Complexity – The more complex the part, the better DDM will provide you with the desired outcome. DDM builds parts layer upon layer and is unbiased to geometry. It can build undercuts, trap volumes and work with zero draft. Rapid Tooling can also build parts with undercuts, but the cost increases.

Material – The more material options you need, the better RT will perform. Though DDM can build parts with ABS, PC and PPSF, Rapid Tooling can produce parts from those materials, and more. It is common for Rapid Tools to produce parts from Delrin, Ultem, Santoprene, Glass-Filled materials, PEEK, and PVC among many others.

Quantity – The more parts you need, the easier and cost effective it is to use RT. While there is an initial cost for RT in building the tooling, the higher quantity of parts absorbs the cost. Rapid Tooling can produce thousands of parts very efficiently.

Tolerance – The more accurate the tolerance your parts require, then RT will be the best method. DDM can hold good tolerances with repeatability, but today’s High Speed Mills will hold to tight tolerances.

Revisions – The more revisions you are going to have in your design cycle, the better DDM looks. DDM builds parts without tooling. You can make revision changes relatively quickly by changing the digital design, without the need for modifying tooling.

Surface Finish – If you need a more refined or smoother surface finish, then RT is the right choice. High Speed Milling running over 30,000 rpm’s and using .3 mm (.012”) diameter cutters that can produce a very smooth surface finish. You can also polish or texture the RT aluminum mold for your desired finish.

Speed – The more response you need, then DDM is your best choice. With DDM you can produce your first parts in 1 to 3 days. FDM, SLS SLA, Polyjet, or EOS can build your parts immediately without tooling or fixtures.

To the left is a helpful guideline for your next project. You will need to evaluate the importance of each item and include the costs in your overall assessment. We also encourage you to evaluate each project independently. Just because DDM and/or RT does not work for your first application, your needs may change for your second application. You owe it to yourself and your company to keep evaluating RT and DDM for your low volume production needs.

DISPELLING THE MYTHS OF RAPID TOOLING

Due to the inefficiencies of early methods used for “Prototype Tooling”, Rapid Tooling has been slow to take off. Methods such as Keltool, Direct Aim, and Laser Form (SLS) tooling were very niche specific. These tools fell short when it came to tolerance, surface finish, quantities, and the materials that you could use with them. Because of this, many people continue to believe this is true with today’s technologies. People continue to believe aluminum molds can not shoot different materials, run high volumes, shoot parts with undercuts, or make mold revisions. This has all been proven FALSE!

TODAY’S RAPID TOOLING

Today’s Rapid Tooling is being constructed with 7075 T-6 aluminum and machined using High Speed Mills running over 30,000 rpm. Today’s RT can be made to produce parts with undercuts, run multiple materials, can be modified for many revisions, and run tens of thousands of parts.

This mold shows a hand pick-out to capture the external threaded undercut.

- You can capture undercuts - Rapid Tooling uses machined hand pick-outs and manual slides to capture undercut features in the mold. It may take a little more time during the injection mold pressing, but for low volume products this should not be an issue because the cost savings in tooling can offset the cost of a few seconds.

- You can make tool revisions - Aluminum tools can be welded, re-machined, inserted, polished, and textured. This is a cost effective way to get through your design concept before you spend your budget on production molds.

- You can run exotic materials - Not only can you run the staple materials such as ABS, PC, Santoprene, Nylons, etc, but you can also run engineering grade materials like Ultem, PEEK, PPSF, mineral-filled, and glass-filled materials.

- You can run a lot of parts - Aluminum tools can run thousands of parts without wear on the tools. It does depend on part geometry and material choice, but is not uncommon to run 15,000 to 50,000 parts off an aluminum tool.

Low Volume Production (Section 3)

In this finale, parts will be identified and compared between Direct Digital Manufacturing (DDM) and Rapid Tooling (RT) using aluminum molds. Again, as described in the previous articles, you will need to decide what is important in the plastic part to you and your project. Is it tolerance, speed, surface finish, material, etc? These charts are going to make the assumption that you have already considered your requirements and now it is strictly up to cost.

To recap, DDM is defined as a direct production of finished goods from additive manufacturing technologies. The additive manufacturing technology that we are using in our comparison is Fused Deposition Manufacturing (FDM). FDM is the process of extruding plastic to build a part layer upon layer. Commonly used materials are ABS, PC and PPSF.

Before you see the price comparisons here is how we came up with the pricing to make sure the caparisons are accurate. The cost of Rapid Tooling Unit Pricing has the cost of unit pricing and the cost of the tooling. Direct Digital Manufacturing Unit Pricing has the cost of programming, build time, and post processing to make the parts.

PART #1 LATCH

This latch is 3” x 1 ½” x ½” made from a white ABS. With aluminum tooling this design is a straight pull with no undercuts. This part would be considered a simple part with no complex geometry. In showing the data, the breakeven point would be at the quantity of 250 units. To buy less than 250 units, it is more cost effective to use DDM and after 250 units, an aluminum tool is more beneficial.

PART #2 SPACER

This Spacer is made of a black ABS and has the dimensions of 7.21” x 5.95” x .57”. The breakeven number would be at a quantity of 75 units. Again, this part is a simple part with no complex geometry. This product life was only meant to be 60 units and DDM was the perfect fit. The parts were completed in 3-4 days without any tooling cost.

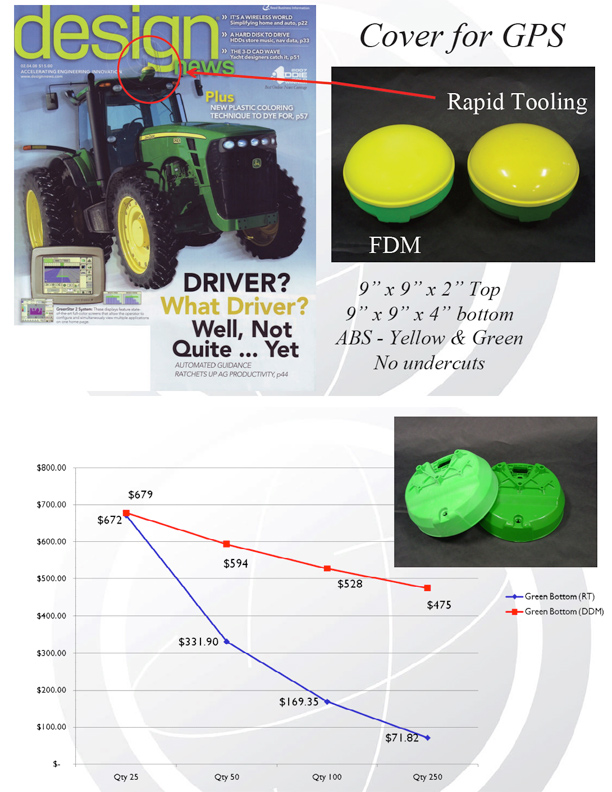

PART #3 GPS COVER

The top cover dimensions are 9” x 9” x 2” made from a yellow ABS. The breakeven area is around 30 parts. This customer ended up needing thousands of parts to fulfill their low-volume production needs so the aluminum tool was very beneficial. The tools were completed in 2-3 weeks and used for over 10,000 parts. The matrix shows that you need to understand the quantities for your product to best choose your manufacturing method.

PART #4 CIRCUIT PLUG

This circuit plug has complex geometries. We made assumptions in this matrix to show data with this part having one, two and three undercuts to show how different the breakeven points can be based on geometry. DDM has no biases to complexity, because it builds layer upon layer. Rapid Tooling needs to capture these features with a hand pick-out. The plug is 3 “ x 2” x 1” made from black polycarbonate. Depending on the complexity, the breakeven point floats between 100 and 220 parts.

Choosing your manufacturing method greatly depends on the size and the complexity of your part. Use these matrixes to better understand where the value add is in each of these technologies. Be sure to always evaluate and re-evaluate your projects because each of these methods may not be niche specific.

FINAL THOUGHTS

As we see our trends hold true to produce lower-volume products with higher margins, overseas suppliers are less competitive. The need for speed is at a premium along with quality. Commodity buyers are being asked to evaluate best ways to produce new products. My suggestion is that it begins before that. Engineers and designers need to be aware of these options. Imagine if you are designing your next product knowing you will be using DDM. Using this method of production, you can design without draft, radii and design parts with trapped volume or reverse undercuts. Without deciding this upfront, the design must be designed in a traditional fashion. As we come to an end in our 3-part low-volume production discussion, I hope that you have had the courage and the foresight to look to the future of your design and your method of manufacturing. Our country is only as strong as our schools and our manufacturing. Use these technologies and their advantages to keep manufacturing alive and well in the United States. You and your products will benefit for tomorrow.

Written By: Danny Mishek | President, VistaTek